Should You use Spark Plug Anti Seize Lubricants to Peak Torque Rpm

Should You use Spark Plug Anti Seize Lubricants to Peak Torque Rpm? When you are about to replace your old spark plugs with new ones, you need anti-seize removal. In other words, anti-seize are spark plug lubricants for effortless dissembling as the bolts and screws come off quickly.

There are some safe ways to apply anti-seize to protect spark plugs and their neighboring components. The vehicles for either of the types, automotive or aviation manufacturers, have instructions for using anti-seize on their spark plugs.

Also, some brands do not suggest any kind of lubrication. So, today from our own experiences, we will discuss the forms of anti-seize, their necessity, preventions, and substitutes.

What is anti-seize on spark plugs?

Anti-seize on spark plugs are lubricants used when taking them off the socket. As lubrication, anti-seize helps the plugs to loosen up so that they can easily be taken out.

Some spark plug manufacturing brands, such as NGK, and Bosch already provide a coat of anti-seize on their spark plugs so you won’t have to unseized them separately. Also, too much anti-seize is detrimental for the spark plugs, so the brands already follow up.

Does Anti-Seize Affect Torque Spec?

The short answer is yes, anti-seize compounds can impact torque specs, but it depends on the formulation of the compound and how it’s used. Anti-seize compounds are designed to aid in ensuring the bolts or nuts are tightened properly.

They work by filling any defects or blemishes in the threads, allowing the fastener to be tightened more effectively. This will help ensure that the connection is secure and prevent over-tightening, which can damage the threads.

Is It Recommended To Put Anti-Seize On Spark Plugs?

When it comes to spark plugs, you last want them to become stuck in the engine. But many people ask if putting anti-seize on spark plugs is recommended. The simple answer is no.

Where Should You Never Apply Lubricant Or Anti-Seize On A Spark Plug?

Firstly, you should never apply lubricant or anti-seize to the thread of a spark plug since it can eventually cause corrosion and damage the spark plug internally.

In addition, you should never lubricate a spark plug’s sealing or heat transfer surfaces. This is because the sealant or anti-seize applied to these areas can reduce the heat transfer capability and allow heat to be transferred to other engine areas, ultimately causing engine wear or premature failure.

Also, you should never apply lubricant or anti-seize to the spark plug gap. This is because the spark plug gap is the space between the electrodes, and if the gap becomes filled with any type of lubricant or anti-seize, it can interfere with the spark and cause misfiring.

Do Iridium Spark Plugs Need Anti Seize

The answer is a resounding no. As mentioned, iridium is incredibly durable, so much so that it does not need any lubrication or additional protection during installation. In addition, applying anti-seize to the threads could potentially cause more harm than good by introducing too much lubricant into the installation.

Spark plug anti-seize compound:

Where spark plug anti-seize compound produces the needed lubrication, too much of it will cause the plug to over-torque. So, you have chances of distorting the plugs while DYing with anti-seize compounds, which might result in engine misfire, spark plug thread damage, combustion gas leaks, and many more.

That is why modern spark plugs come anti-seize to reduce or diminish the chances of self-seizing the plugs. Spark plugs with an anti-seize compound are from NGK, ACDelco, Autolite, and Bosch.

What is spark plug grease?

Spark plug grease is a somewhat semi-solid form of lubricant known as anti-seize. It does a similar job of loosening the tools like anti-seize. However, as grease has a high viscosity, the greased tools obtain high frictional characteristics.

Also, greasing the tools retain water or moisture so that no rust or corrosion can harm the plugs. Greasing a spark plug is an occasional job, as its density of it stays for a long.

Spark plug grease is necessary

Greasing the spark plug can be a bonus maintenance step but is not required. Nowadays, spark plugs contain certain types of plating, such as onyx or nickel-chrome on the outside that prevent them from immature corrosion.

Also, sometimes DIYs lead to over-greasing which can cause the opposite of what you wanted. Such as the roller threads might lose friction, there can be an accidental opening of specific bolts and screws, and much more.

What is copper grease?

Copper grease is a widely used term in the automotive industry, a term for an anti-seize compound. It is made from a combination of corrosion inhibitors and fine copper particles in the procedure by mixing oil and soap.

As a result, the copper grease obtains a high viscosity compared to a regular anti-seize compound. So, the grease sticks and stays longer on the material applied and does its job of preventing seizure and corrosion.

Dielectric grease on spark plugs

One of type of spark plug grease is dielectric grease, which is silicone-based. It means the dielectric one has more viscosity along with a sticky texture. For this, dielectric grease is mainly used as a connector for spark plugs with its wires.

Also, dielectric grease is called tune-up grease with high water repellency and a protective barrier against rust and corrosion for spark plugs.

Substitute for dielectric grease

Vaseline is a close and cheap substitute for dielectric grease. However, you should apply it with caution as it contains petroleum and has lots of drawbacks, and petroleum can leave distillates on the metallic tools.

Also, petroleum is combustible and can destroy the rubbers of the spark plugs soon. Even though Vaseline is an available substitute, it should be avoided to use on automotive car components.

Brake grease vs. anti-seize: All you need to know

The anti-seize compound has a little bit of grease carrier and high solid contents in it that lubricates and stays for a long. It has high-heat resistance and works in the most elevated temperature environments due to those elements.

Also, anti-seize is great for high-pressure movements and high-contact applications. Whereas, brake grease is the opposite of anti-seize. It cannot withstand high heat, which is more than 400 degrees Fahrenheit.

That is because they do not have a grease carrier and highly solid components in them like anti-seize. Moreover, brake grease has low-contact applications and low-pressure movements.

6 FACTS TO KNOW ABOUT SPARK PLUGS-Your engine relies on spark plugs every day

BEFORE JUMPING INTO DETAILS YOU MUST KNOW ABOUT how to tell if a spark plug is misfiring, what spark plugs do spark plug sockets, the benefits of changing spark plugs, what happens when spark plugs go bad, how long spark plugs last, spark plug problems, what to do after changing spark plugs.

1. Anti-seize

Anti-seize is lubricant used on spark plugs to reduce their torque value and prevent certain areas from corroding. However, anti-seize has lots of disadvantages if not used properly, such as thread breakage, cylinder head erosion, over-tightening of spark plugs, and engine damage that could be the worst.

Therefore, modern spark plugs already come pre-protected and lubricated, so users don’t have to use anti-seize by themselves.

2. Spark plug torque

Torque is the ability of a spark plug to perform by dissipating heat on a specific torque requirement. The requirement is different within brands.

Having an under-torque can cause spark plug or engine damage and over-torque gas leakage, pre-ignition, and much more.

3. Oil on spark plug threads

one of the signs of a wrong spark plug thread is oil on spark plug threads. Oil-fouling happens when the O-ring valve tube seal leaks. It won’t create much of a problem unless you don’t replace the leaked tubes or the entire spark plug set.

4. Spark plug thread size

Spark plug threads are measured in two forms, diameters and pitches. Unfortunately, the thread size is not universal, so you need to find the right size according to your automobile’s requirements.

5. Gapping fine-wire spark plugs

Gapping the fine-wire spark plugs is a sensitive issue as over-gapping means the spark plug remains unusable. And too much pressure while gapping the electrodes can break or dent them.

Therefore, buy a pre-gapped spark plug set according to your vehicle’s recommendations.

6. Corona stain

Spark plugs acquire corona stains over time, which is a result of high-voltage traveling. Therefore, the spark plugs accumulate oil and debris surrounding the insulator and metal shell that leaves a tan-brown discoloration on them.

Corona stain is nothing a huge matter of concern as it is a naturally occurring substance.

How do gap spark plugs without a tool?

For gapping spark plugs to fit your vehicle’s recommended gap size, you need a proper tool. As they are fragile, so have tendencies of bending and denting fast. Without a professional tool, you can DIY the gaps only if you have professional knowledge of it.

You can use a coin, which is available in everyone’s house. With accuracy, bend the spark plug’s electrode, maintaining the gradual slope. Using coins is economical too.

However, this method is only for copper spark plugs and not for iridium spark plugs as the coin’s metal compound can damage it.

Should I use anti-seize on spark plugs?

Modern spark plug manufacturers do not recommend Anti-seize as it encounters severe engine problems if not used in the proper place and amount. Well-known spark plug brands, such as NGK, Bosch, Autolite, and ACDelco highly discourage the use of anti-seize, also put protective and lubricative agents on their plugs.

How to use anti-seize on spark plugs

While using anti-seize, do follow the aircraft guidelines and use it sparingly. Apply a thin layer of it on the middle of roller threads using fingers or airbus, sparing the electrodes.

A small dab of seizing goes a long way, so make sure you don’t overuse and over-tighten the plugs because highly lubricated plugs are easy to over-tighten. Always choose aluminum or nickel-based anti-seize if your spark plugs have stainless steel material.

The best anti-seize for spark plugs

Are spark plugs pre-gapped?

Spark plugs in older days needed customized gapping. The modern spark plugs are pre-gapped for users’ ease. Still, one should cross-check whether the gap is a perfect fit as per their vehicle’s recommendations or not. You can customize a tiny spec of the pre-gapped spark plug size, but not too much. Or else the plug will bend or break.

Anti-seize on spark plugs or not: How to understand

Modern spark plug manufacturers do not encourage putting anti-seize on spark plugs. Because users often overuse them, which leads to engine problems such as misfiring and damage. Therefore, the manufacturers came up with the idea to pre-seize their spark plugs.

Anti-seize on copper spark plugs:

Since anti-seize compounds have electric conductive ingredients in them, they come in contact with the high conductive copper material and start to misfire the engine with a multiplier effect. The cylinder head and galling will also get damaged due to over-torquing when applied even a little extra anti-seize.

anti-seize copper vs. aluminum: Let’s have a short review

Copper anti-seize has excellent anti-seize properties with high-temperature resistance. In battery terminals, it protects against corrosion and forms a secure seal on the applied components. Disk brake sequels can only be prevented by copper anti-seize.

Whereas, aluminum anti-seize has excellent heat resistance and is non-reactive to stainless steel, unlike copper anti-seize. Also, aluminum ones are easy to find in the market.

Anti-seize on silver spark plugs:

Silver spark plugs are already designed to prevent corrosion, chemical buildup, and moisture-wicking properties. They already have a natural release agent in them which works as a lubricant. So, silver spark plugs do not need anti-seize already.

Spark plug material

1. Copper: Copper is the most common type of material used in spark plugs for its high heat conductivity, which means they heat up fast and cool down fast too. Copper spark plugs have the best performance as it ignites the fuel-air mixture fast and starts the engine quickly. However, the overall longevity of copper plugs is not good. So, they need more maintenance and frequent replacement.

2. Platinum: If platinum spark plugs are well-taken care of, they can last up to 100,000 miles. Yes, they are that durable to hold their sharp edge longest compared to a traditional spark plug. Platinum spark plugs also have self-cleaning properties to avoid foul buildup. However, their heat conductivity is low.

3. Iridium: Iridium spark plugs are famous for enhancing a much better fuel economy. They ignite fast and start the engine fast, providing smooth acceleration and idling to your car too. Also, iridium spark plugs have the highest melting point than any other types of spark plugs, so they are proven to last eight times more than conventional spark plugs.

4. Double platinum: Just it contains an extra electrode, which differentiates it from single platinum spark plugs. They have more than decent longevity; however, the performance is not as commendable as it should have. Double platinum spark plugs are mainly used in spark distributors’ waste ignition systems.

Spark plug grease substitute

Vaseline, white lithium grease, and dielectric grease are widely used in wire connectors of motorcycles and automobiles.

Is dielectric grease necessary for spark plugs?

First of all, don’t tighten spark plugs during installation. Apply a thin coating of dielectric grease to the porcelain and terminal of the front part because it is good preventative maintenance including spark plug wires. Dielectric grease, or tune-up grease, is a silicone-based grease that repels moisture and protects electrical connections against corrosion.

If your engine has the more modern ‘COP’ system (coil-on-plug) then lube the spark plug boot with dielectric grease, this helps prevent misfires and makes removing easier in the future.

lithium grease on spark plugs

White lithium grease is applicable. Moreover, lithium grease is petroleum-based, do not use plastics and rubber which it’ll cause these to prematurely fail.

Copper vs. iridium – copper vs. platinum spark plugs

Overall, comparing copper spark plugs with iridium and platinum spark plugs shows copper has high heat conductivity hence the spark plugs have faster action. Platinum and iridium spark plugs’ performance is a bit slower compared to copper spark plugs. However, copper ones have the shortest life span, whereas platinum has longer and iridium the longest because they have self-maintaining and excellent anti-wear characteristics.

Iridium spark plugs vs. copper

Copper spark plugs are the most common, so they are cheaper compared to iridium ones. Also, iridium spark plugs last 7x more than copper spark plugs with their durable build and self-maintaining properties. It means copper spark plugs need frequent replacements and more maintenance. However, iridium plugs are less heat-conductive so their performance is slower than copper plugs, but they make the engine perform much better.

How long do copper spark plugs last?

Copper plugs have the least lifespan compared to other material spark plugs. The primary cause is their build, as that is not tensile. Plus, if not maintained well, they have a high chance of fouling and overheating fast. So, they last a maximum of 20,000 miles, which is around 1.5-2 years, depending on your journey.

Spark plug anti-seize for aluminum heads:

Whether to use Anti-seize on aluminum heads or not, remains a big question. As a rule of thumb, anti-seize is only meant to be put on spark plug roller threads. They contain dissimilar metallic compounds and can corrode, so aluminum heads should be avoided while applying to seize.

How to apply anti-seize to spark plugs:

You should apply a small dab of anti-seize till the spark plug gasket surface starts from the second roller thread. Make sure you avoid the first thread of the spark plug at every cost. Also, do not over-apply the seizure as it will lead to detrimental consequences.

where to put anti-seize on spark plugs:

Put a thin layer of anti-seize on spark plugs’ roller thread of it only, that too starting from the second strand of thread till the gasket surface.

About spark plug threads:

Spark plug threads screw down into the cylinder head. They come in sizes that refer to what size cylinder they need to get screwed. The first number is referred to as thread pitch and the second one is the thread diameter.

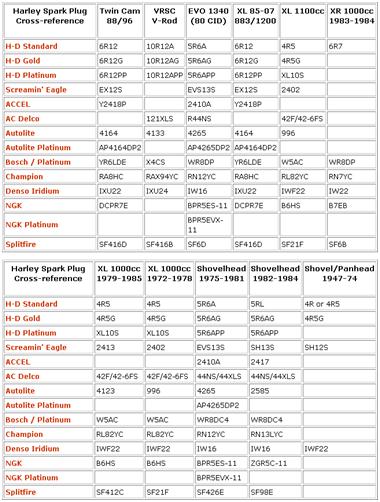

Harley Davidson spark plug gap chart:

Below is the Harley Davidson spark plug gap chart which is easily cross-referred by some of the well-known spark plug brands. If you have ever used the referred brands, you will find it easier to find the HD spark plug gap.

Resources:https://dut.barachuufservpro.pw/harley-davidson-spark-plug-gap-chart.html

RELATED SPARK PLUGS ARTICLE(S)-

- Spark Plug for 5.4 Triton

- How to tell if a spark plug is bad by looking at it

- What causes bad spark plugs

- Bad spark plug sound

- Symptoms of bad spark plug wires

- What happens when spark plugs go bad?

- Bad spark plug symptoms motorcycle

- Spark Plugs for 5.3 Vortec

- What does a bad spark plug look like

- What heat range spark plug should I use

- How to read spark plugs for tuning

- SPARK PLUG ANTI SEIZE

FAQ

Is anti-seize necessary for spark plugs?

No, anti-seize is not obligatory for spark plugs, as many spark plug brands pre-seize their spark plugs so that users don’t have to apply anti-seize themselves. Because using anti-seize without knowledge can detriment the engine.

Do ngk spark plugs come pre gapped/are ngk spark plugs pre gapped?

Yes, NGK spark plugs are pre-gapped and might need customization in some cases. To prevent mis-gaping, you should take care of the plugs well so that they don’t dent. For customization, make sure the gap is increased or decreased by 0.008 inches from the pre-gapped position.

Is ngk spark plugs well?

NGK spark plugs are one of the best spark plug brands in the market. Their durability, high heat tampering, and trivalent plating make them stand in the crowd. Chrome or silver plating is always used on their roller threads for preventing moisture, rust, and easy removal without the need for seizing.

![5 Best Spark Plugs for 5.7 Hemi [Reviews & Guide] in 2023](https://torqueadvisor.com/wp-content/uploads/2021/02/Best-Spark-Plugs-For-5.7-Hemi-1.jpg)